A structured packing station allows workers to access tools and materials quickly, reducing the time spent walking between areas. With optimized workflow layouts and packing benches designed for quick access to cartons, tape, labels, and scanners, your team can process more orders in less time—resulting in faster delivery and improved customer satisfaction.

Packing errors—such as mislabeling, incorrect items, or poor sealing—can lead to costly returns and customer complaints. By integrating smart accessories like label holders, tool panels, and overhead lighting into your packing workbench, you create a controlled environment that minimizes human error and protects fragile goods during packaging.

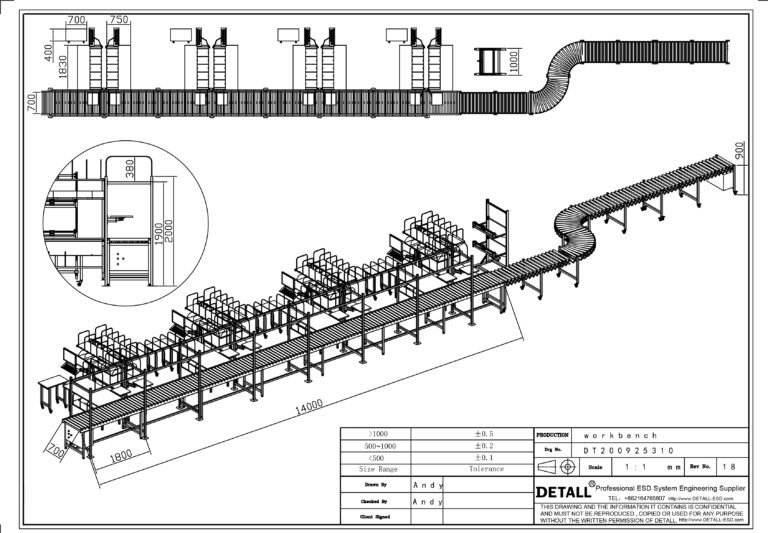

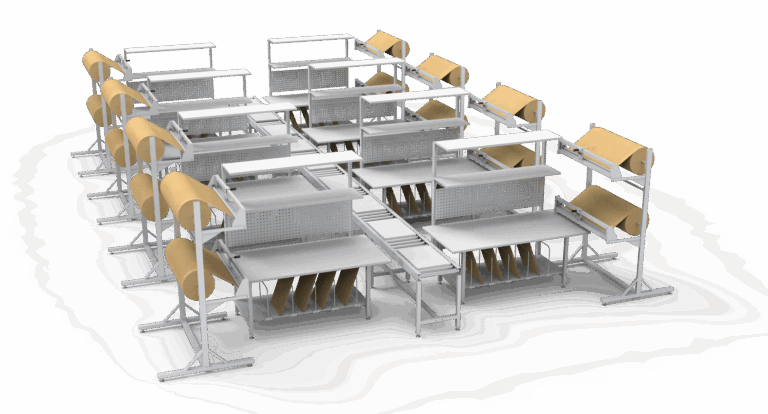

An efficient packing area streamlines your internal logistics by aligning packing tables, conveyors, and storage systems according to your operation’s specific needs. Whether using U-shaped, straight-line, or modular layouts, you can eliminate unnecessary motion, reduce clutter, and maximize usable floor space—leading to smoother, more scalable warehouse operations.

Packing workstations designed with ergonomic principles—like adjustable height tables, anti-fatigue mats, and easy-reach shelves—reduce strain and injury. This not only enhances comfort and productivity but also supports compliance with workplace safety standards, decreasing long-term costs associated with worker compensation or downtime.

Choosing the right equipment for your packing area can dramatically improve workflow, reduce packaging time, and lower shipping errors. Below are the essential tools commonly used in logistics, warehousing, and e-commerce fulfillment centers.

Designing an efficient packaging workstation is key to maximizing productivity and minimizing errors in logistics and fulfillment operations. Our recommended layouts are based on real-world workflows and ergonomic principles, helping businesses streamline processes from packing to labeling and shipping. Whether you’re organizing a single packing station or a full-scale assembly line, these layout solutions are optimized for:

Efficient material flow – Minimizing unnecessary movement between workstations

Ergonomic positioning – Reducing worker fatigue with height-adjustable tables and smart placements

Storage accessibility – Integrating shelving, carton flow racks, and tool organization

Scalability – Easily expandable designs for future growth

These layouts are ideal for e-commerce fulfillment centers, industrial packing zones, and third-party logistics warehouses, supporting both manual and automated packing operations.

A packing station is a dedicated workstation where order items are consolidated, quality-checked, packaged, labeled, and staged for shipping. Proper packing station design—with tools, supplies, and workflow aligned—can significantly improve operational speed, reduce packing errors, and enhance customer fulfillment efficiency.

Essential tasks commonly include:

Order consolidation and quality control

Packing and void-fill application

Label printing and box sealing

Staging packed orders for pickup

Understanding these functions helps define the right equipment and layout for your packaging workstation.

An efficient packing workflow typically follows a straight-line layout. From order consolidation, to packing, to labeling and staging, materials and operators remain within arm’s reach—minimizing unnecessary motion and speeding up throughput.

A well-equipped station includes:

Packing bench with shelving/tool panels

Label printer, scanner, tape dispenser

Heat sealers, scales, void-fill machines

Organized storage for boxes, labels, cushioning materials

This ensures orderly workflow and consistent output quality.

An ergonomic layout places frequently used tools within easy reach and uses height-adjustable workbenches, anti-fatigue mats, and ergonomic chairs. This not only increases productivity, but also reduces physical fatigue and supports safe packing operations.

Yes. Modern packing systems offer modular designs allowing add-ons such as extra shelving, conveyors, and accessories. As your business grows, you can easily expand or adjust the layout to match increasing workload or new workflow needs.