- How to DIY Your Custom Workbench: Step-by-Step Guide

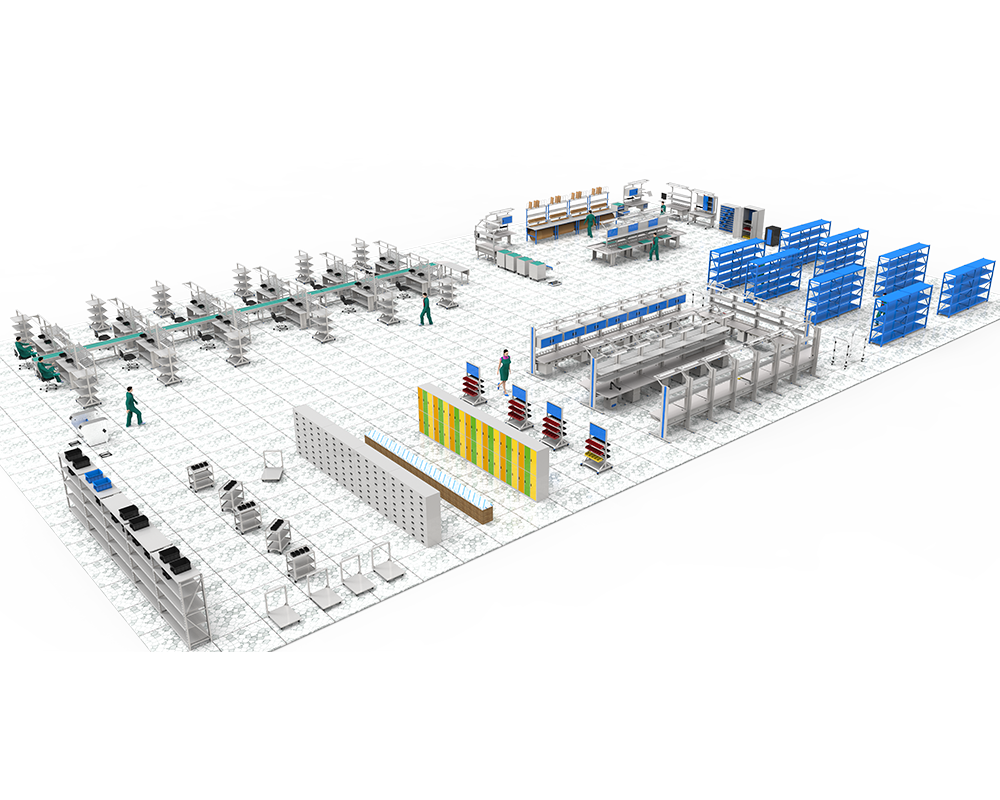

Building a workbench that perfectly fits your needs can greatly improve your workflow and workspace efficiency. Therefore, follow these steps to create a custom workbench tailored specifically for you.

1. Define Your Needs and Functions

Start by outlining the main tasks and activities you’ll perform on the workbench. Consider:

- The space you need

- Storage requirements

- Functional layout

For example, determine if you need nearby power outlets, lighting, or computer installation. If electricity is needed, plan for wiring, network ports, sockets, lighting, and cable management ahead of time.

1.1 Assessing Your Space

Measure your available workspace carefully. This helps in making sure the workbench fits perfectly without overcrowding your area.

1.2 Considering Power and Lighting Needs

Power outlets and lighting are crucial for a functional workbench. Moreover, proper lighting reduces eye strain and increases precision in your work.

2. Planning and Design

Design your workbench layout based on your requirements. Consider the work area, storage space, and future expandability.

2.1 Using Sketches or Software

Next, use sketches or design software to create a detailed plan. This will help you visualize the final product and make adjustments before building.

3. Selecting Materials

Choose materials that suit your design and needs. Common options include wood and metal.

3.1 Why Choose Aluminum Profiles?

If you lack specialized tools, aluminum profiles are recommended due to their standardized sizes and easy assembly with connectors. In addition, they require less cutting and precise measurements.

3.2 Enhancing Strength and Appearance

For a stronger, cleaner finish, design fixing holes in the profiles to hide connection blocks. You can also incorporate sheet metal parts for additional features or refer to professional aluminum workbench modules for inspiration.

Sheet metal workbenches allow various styles and colors and can be customized with functional components through metal processing services.

4. Prepare Your Tools

Select tools based on your workbench type:

- For wooden benches: carpentry tools, cutting tools, rivet pullers, and fasteners.

- For aluminum profiles: connectors and bolts typically provided by suppliers. Choose profiles by size and thickness, commonly 40x40x2mm for workbenches.

- For sheet metal benches: metal bending, welding, and painting may require professional manufacturing based on your designs.

5. Frame Construction

Build the frame using your chosen materials, ensuring a solid structure.

5.1 Choosing the Structure Type

Choose the structure type based on use. For ergonomic comfort, the standard working height is around 750mm for sitting or 900mm for standing, adjustable to your height.

Lifting workbenches come in hand-operated or electric types, with load capacities varying accordingly.